Designer & Manufacturer of Worm Reduction Gearboxes

Double reduction worm gearbox – JN Gears the top Double reduction worm gearbox manufacturer is well-equipped with sufficient infrastructure and a well-experienced team of engineers. We ensure the delivery of inline helical geared motor on time, exactly according to your demands. We are specialized in making gearboxes of all types. Tell us your demands and requirements. We can match all your needs with the required quality. As the best industrial gearbox suppliers, we serve industries such as aviation, agriculture, mining and quarrying, automotive and more.

JS Gears – Worm Reduction Gearbox Manufacturers and Suppliers

J N Gears is a top player among the Worm reduction gearbox manufactures and suppliers. We manufacture and supply varied types of gears and gearbox that are specific to your industries. We can tailor-make a Worm Reduction gearbox to suit the requirements and specifications of your applications. Tell us your requirements, and we can help you with constructive suggestions to engineering a Double Reduction Worm geabox motor that is suitable for highly challenging and the hardest environments. Every piece of gearbox that goes out of our production unit meets world-class quality standards, and thus we are the favourite Double Reduction Worm gearbox suppliers for all our clients across India and abroad.

We are here to provide complete gear solutions and services to all our clients from anywhere in the world. We design and manufacture F series helical geared motor that achieves high performance to meet the requirements of small, medium and heavy-duty industries. Are you looking for suitable extruder gearbox manufacturers to use in a wide variety of applications that run in the most challenging environments? Contact us today, and we can go beyond your expectation to fulfill your demands on time.

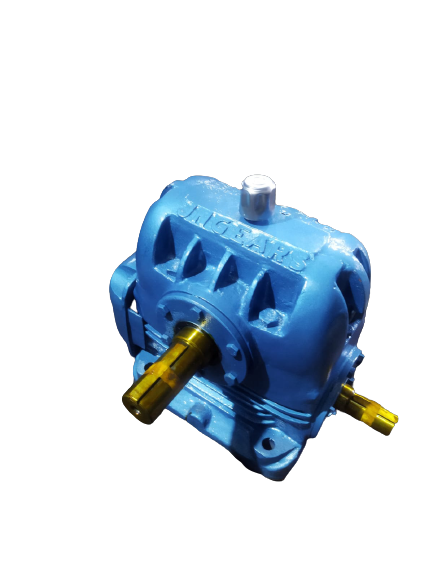

Description

Foot Mounted , Under / Over driven , Horizontal / Flange Mounted worm Reduction Gearbox.

| Size | Ratio |

| U-200 to U-1700 | 5:1 to 70:1 |

Foot Mounted Vertical Gearbox

| Size | Ratio |

| V-200 to V1700 | 5:1 to 70:1 |

Power – .25 KW to 200 KW

Case – Cast Iron & Steel Fabricated

Worm Shoft Material – SAE – 8620/20MnCr5 Harden & Profile Ground.

Worm Wheel Material – Pb-2 (Phosphorus Bronze)

Bearing – Tapper & Boll Bearing

Application

- Conveyors

- Rotary Kiln

- Ball Mills

- Raw Mill

- Coal Mill

- Travelling Grate

- Nodulizer

- Apron Conveyours

- Elevator Drives

- Separator Drive

- Bulk Materials Handling

- Classifier

- Conveyor Drive

- Bucket

- Slew

- Cane Carrier

- Cane Shredders

- Pressure Feeders

- Diffuser

- Crystalliser

- Rake Elevator / Elevator

- Feeder Table

- Main Mill Drive

- Cane Chopper

- Belt Conveyors

- Screw Conveyors

- Bucket Elevator

- Air Preheater

- Mini Hydro Plant

- Slurry Pump

- Agitator

- Mixer

- Mixer Drive

- Calander Drive

- Small & Medium Wind Turbine

- Extruder Drive

- Vertical Extruder Drive

- Screw Press

- Digesters

- Rotary Dryer

- Feeder

- Apron Feeders

- Rotary Wagon Tippler

- Ring Granulator

- Roller Screen

- Furnace Tilt Drives

- Hot & Cold Rolling Mills

- Levellers

- Shears

- Tube Drawing Mill

- Roll Stand

- Hot Sizing Mill

- Heavy Duty Rolling Mill

- Coiler / Uncoiler

- Tension / Pay off Rell

- Pinion Stand (Rolling Mill)

- Kernel Expellers

- Process Applications

- Crusher

- PQF drive of Seamless Tube

- Bridle Drive

- Briquetting

- Flattener Drive

- Piercing Mill

- Speed Change – Steel Rolling Mills

- Main Hoist

- Long Travle

- Cro

Industries

- Cement Industry

- Sugar Industry

- Steel Industry

- Power Industry

- Material Handling Industry

- Chemical Industry

- Palm Oil Industry

- Crane Industry

- Rubber Industry

- PAPER INDUSTRY