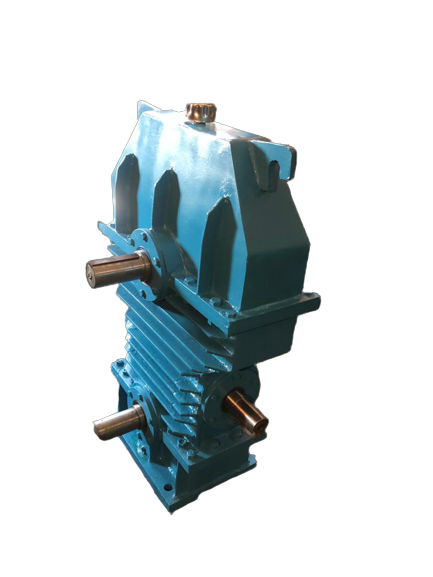

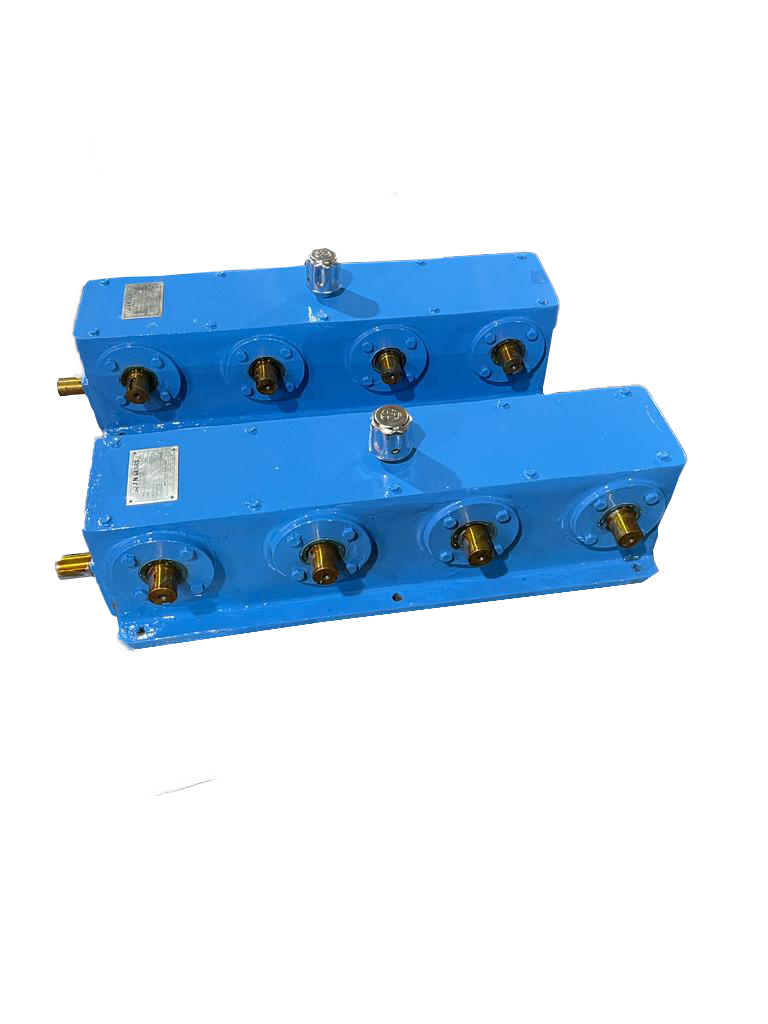

Designer & Manufacturer of Customized Gearbox

Custom manufacturing gearboxes

Custom manufacturing of gearboxes involves designing and building gearboxes to meet the specific needs and requirements of a customer. This process typically involves working closely with the customer to understand their application and develop a gearbox solution that meets their requirements.

Custom gearbox manufacturing may involve a range of activities, including:

- Determining the appropriate gearbox type and configuration for the application

- Selecting materials and components that will ensure the gearbox’s reliability and performance

- Designing and testing prototypes to ensure that the gearbox meets the customer’s specifications

- Manufacturing the final product using advanced techniques and equipment

- Providing support and assistance throughout the process to ensure customer satisfaction

Custom manufacturing of gearboxes can be a complex and specialized process, requiring expertise in gearbox design and manufacturing as well as a thorough understanding of the customer’s application. Companies that offer custom gearbox manufacturing services typically have a team of professionals with the necessary skills and experience to handle this type of work.

Custom gearboxes are gearboxes that are designed and built to meet the specific needs and requirements of a customer. The type of custom gearbox that is best suited for a particular application will depend on the customer’s specific needs and requirements, as well as the performance and operational characteristics of the gearbox.

There are many different types of gearboxes that can be customized, including helical, worm, bevel, and planetary gearboxes. Each type of gearbox has its own unique features and characteristics that make it well suited for certain applications. For example, helical gearboxes are known for their smooth operation and ability to transmit high torque, while worm gearboxes are often used for high reduction ratios and applications where high torque is required. Bevel gearboxes are often used to transmit power at a 90-degree angle or change the direction of rotation, and planetary gearboxes are known for their high reduction ratios and precise torque control.

Custom gearboxes can be designed and built to meet a wide range of requirements, including specific sizes, ratios, materials, and performance specifications. Companies that offer custom gearbox manufacturing services typically have the expertise and capabilities to design and build gearboxes to meet the unique needs of their customers.

Custom gearbox manufacturing involves designing and building gearboxes to meet the specific needs and requirements of a customer. This can involve a range of gearbox types and configurations, depending on the customer’s application and requirements. Here are a few examples of types of custom gearbox manufacturing:

- Helical gearbox manufacturing: This involves designing and building custom helical gearboxes, which use helical gears with angled and offset teeth. Helical gearboxes are known for their smooth operation and ability to transmit high torque.

- Worm gearbox manufacturing: This involves designing and building custom worm gearboxes, which use a worm gear (a screw-shaped gear) that engages with a regular spur gear. Worm gearboxes are often used for high reduction ratios and for applications where high torque is required.

- Bevel gearbox manufacturing: This involves designing and building custom bevel gearboxes, which use bevel gears (conical gears with angled teeth) to transmit power at a 90-degree angle or change the direction of rotation.

- Planetary gearbox manufacturing: This involves designing and building custom planetary gearboxes, which use a system of planetary gears (gears that revolve around a central sun gear) to achieve high reduction ratios and precise torque control.

Custom gearbox manufacturing can involve a range of other specialized gearbox types and configurations, depending on the customer’s needs. Companies that offer custom gearbox manufacturing services typically have the expertise and capabilities to handle a wide range of projects.